Commonly used equipment include box and pan brakes brake presses and other specialized machine presses typical products that are made like this are boxes such as electrical enclosures and rectangular ductwork.

Sheet metal bend relief formula.

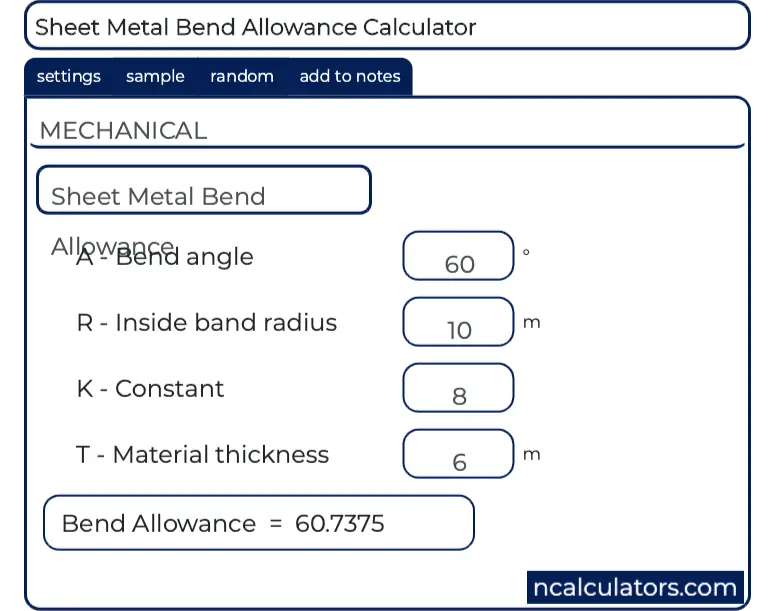

The following illustration shows the equation calculation for determining the bend allowance when forming sheet metal.

Crowning the deflection along a bend.

60 90 and 120 and we will calculate k factor bend allowance and bend deduction for them.

To eliminate this a bend relief is added so the edge of the sheet metal is perpendicular to the bend.

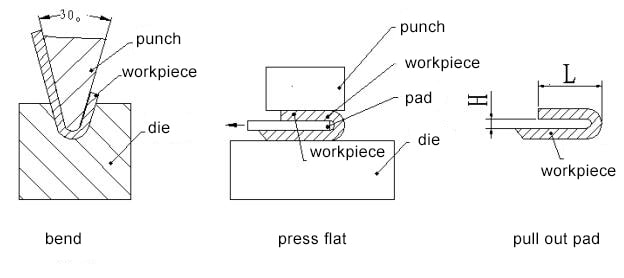

Coining one of the three types of bending for sheet metal where the punch penetrates into the sheet metal under high tonnage forming a consistent bend.

This page also includes a link to a on line sheet metal bend allowance calculator.

Use the minimum bend dimension values in the charts below for your minimum closeness of cutout to a bend.

Bending is one of the most common sheet metal fabrication operations.

When designing parts for laser cutting one should not make holes smaller than the thickness of the material.

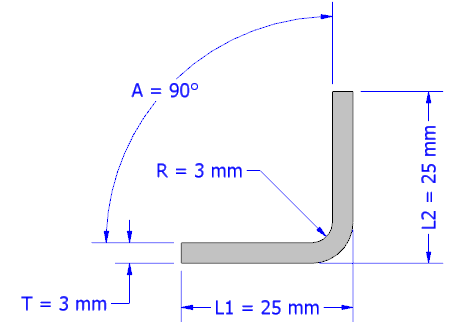

Consider a sheet with a 20 mm thickness and a length of 300 mm as shown in figure 1.

This is done through the application of force on a workpiece.

Most sheet metal materials will conform to the calculations.

Box bending the process of bending a 4 sided sheet metal box.

The diagram shows one such mechanism.

Bending is a manufacturing process that produces a v shape u shape or channel shape along a straight axis in ductile materials most commonly sheet metal.

The bend allowance describes the length of the neutral axis between the bend lines or in other words the arc length of the bend.

Understanding the bend allowance and consequently the bend deduction of a part is a crucial first step to understanding how sheet metal parts are fabricated.

The bend allowance and bend deduction are two measures that relate the bent length of a piece of sheet metal to the flat length.

Sheet metal parts with a minimum of 0 9mm to 20mm in thickness can be manufactured.

A 1 degree tolerance on all bend angles.

One benefit of a bend relief is that it makes the part easier to produce.

Also known as press braking flanging die bending folding and edging this method is used to deform a material to an angular shape.

In general a minimum bend relief is equal to the material thickness plus the inside bend radius.

Sheet metal calculator bend allowance equations and calculator.

Refer to the chart for values for folder as well as various press brake tooling combinations.

Bends in sheet metal are manufactured using sheet metal brakes.

Therefore the bend allowance added to the flange lengths is equal to the total flat.

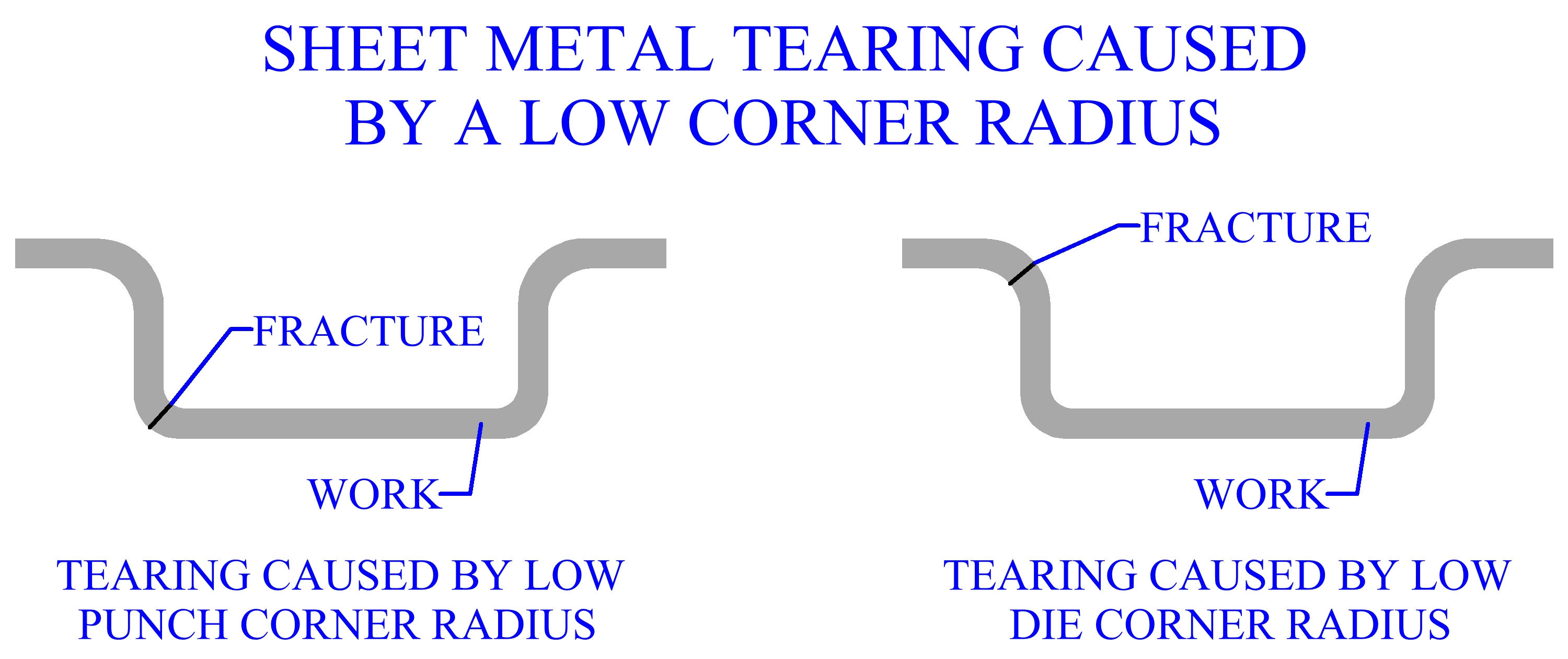

When the sheet metal is put through the process of bending the metal around the bend is deformed and stretched.

Cross break light bends added to sheet metal in order to stiffen its surface.

If it is ok for the metal to rip the minimum bend relief is zero.

The force must exceed the material s yield strength to achieve a plastic deformation.