I tried this method on some black plastic plant pots in order to remove the lettering so that they could be re used at a plant sale.

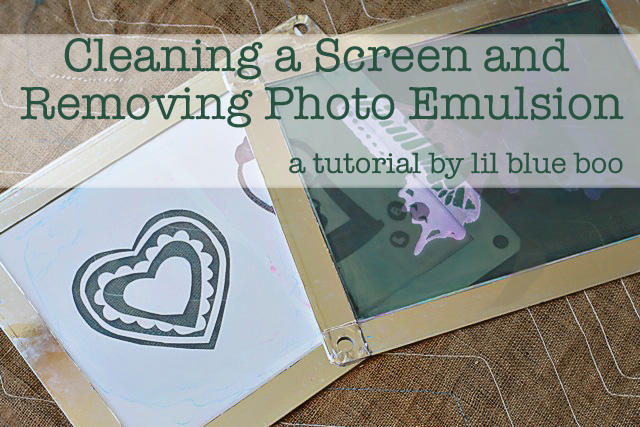

Remove screen printing from acrylic sheet.

Screen printing on acrylic is useful and very relevant for printing labels logos and texts.

An artist can make chemical mistakes in the process such as the improper use of screen filler or even physical mistakes such as accidentally nudging the screen and smearing the design.

It will pass through the open mesh on the screen transferring the pattern onto the.

In this video we showed an easy way of removing screen print from plastic container.

Using a very common household item you can easily remove screen print f.

Screen printing is used for volume production.

Nowadays it has been able to print on plastic products with different surface textures different hardnesses and different shapes and is widely used for decoration of plastic packaging films and.

Toluene is basically a common solvent used to remove inky stains such as paints various chemical reactants rubber glue lacquers leather tanner and disinfectants.

It is fast and economical.

Printing on plastic products includes gravure printing flexographic printing screen printing anti counterfeiting printing and jet printing transfer printing etc special printing methods.

For beginners it is best to purchase a screen from a local screen supply house.

This can result in a ruined logo design which needs to be removed.

Silk screen printing is also used on food containers to list the ingredients and other important information.

This has also been applied in printing drinking glasses id cards candles and organization signboards.

You may also wish to remove the logo from a bought pre printed item.

I use white spirit to remove sticky label residues it works faster and is cheap unfortunately it doesn t work with printed lettering.

Toluene dilutent is your solution in removing such prints be it on a plastic glass or metal surface any smooth surface will do.

After setup apply paint with the squeegee in a uniform even motion in one direction.

Thanks to technology this process has been digitalized meeting the demands of the fast growing population around the world.